Introduction

The beverage packaging industry continues to evolve, with the global glass container market reaching $67.28 billion in 2024. For manufacturers seeking quality wholesale glass soda bottles, understanding direct factory sourcing can significantly impact both product quality and cost efficiency.

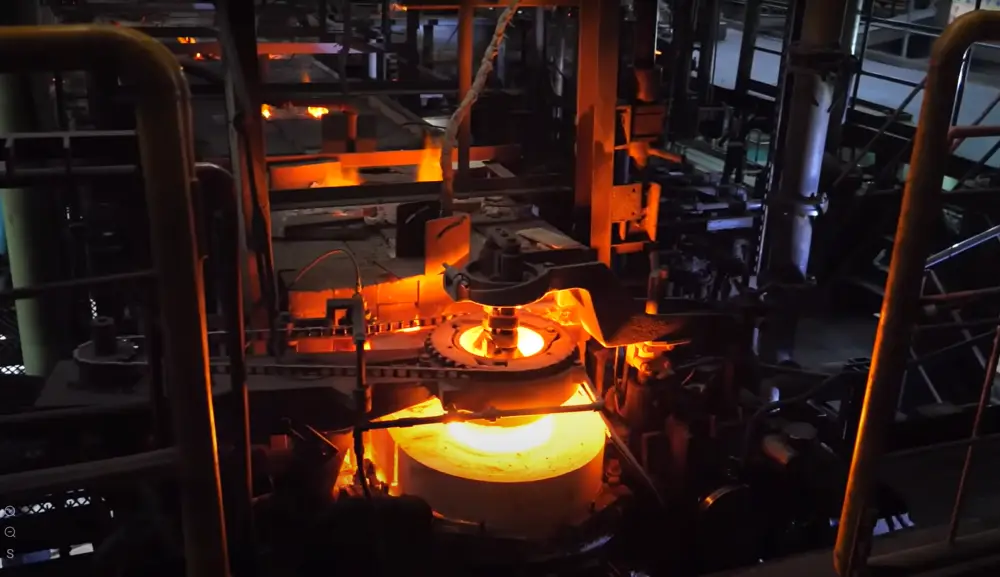

Manufacturing Excellence

Quality Control Process

- Raw Material Inspection: Strict testing of silica sand, soda ash, and limestone

- Batch Mixing Control: Specialized equipment ensuring consistent ratios

- Temperature Monitoring: Precise control during melting (1748°C) and forming

- Automated Inspection: High-speed imaging and defect detection systems

- Final Quality Check: Comprehensive testing for strength and durability

Production Process Table:

| Manufacturing Stage | Temperature | Duration | Quality Control |

|---|---|---|---|

| Batch Mixing | Room temp | 2-3 hours | Chemical analysis |

| Melting | 1748°C | 24 hours | Homogeneity check |

| Forming | 1050-1200°C | 20-30 mins | Dimensional inspection |

| Annealing | 580°C | 120 -180 mins | Stress testing |

Technical Specifications

Glass Properties

- Chemical Durability: High resistance to contents

- Density: 2.52 g/cm³

- Thermal Expansion: 9 ppm/K

- Surface Tension: 315 mJ/m²

Quality Standards

- ISO 9001:2015 Certification

- ASTM C148 Standards

- Non-destructive testing methods

- Automated defect detection

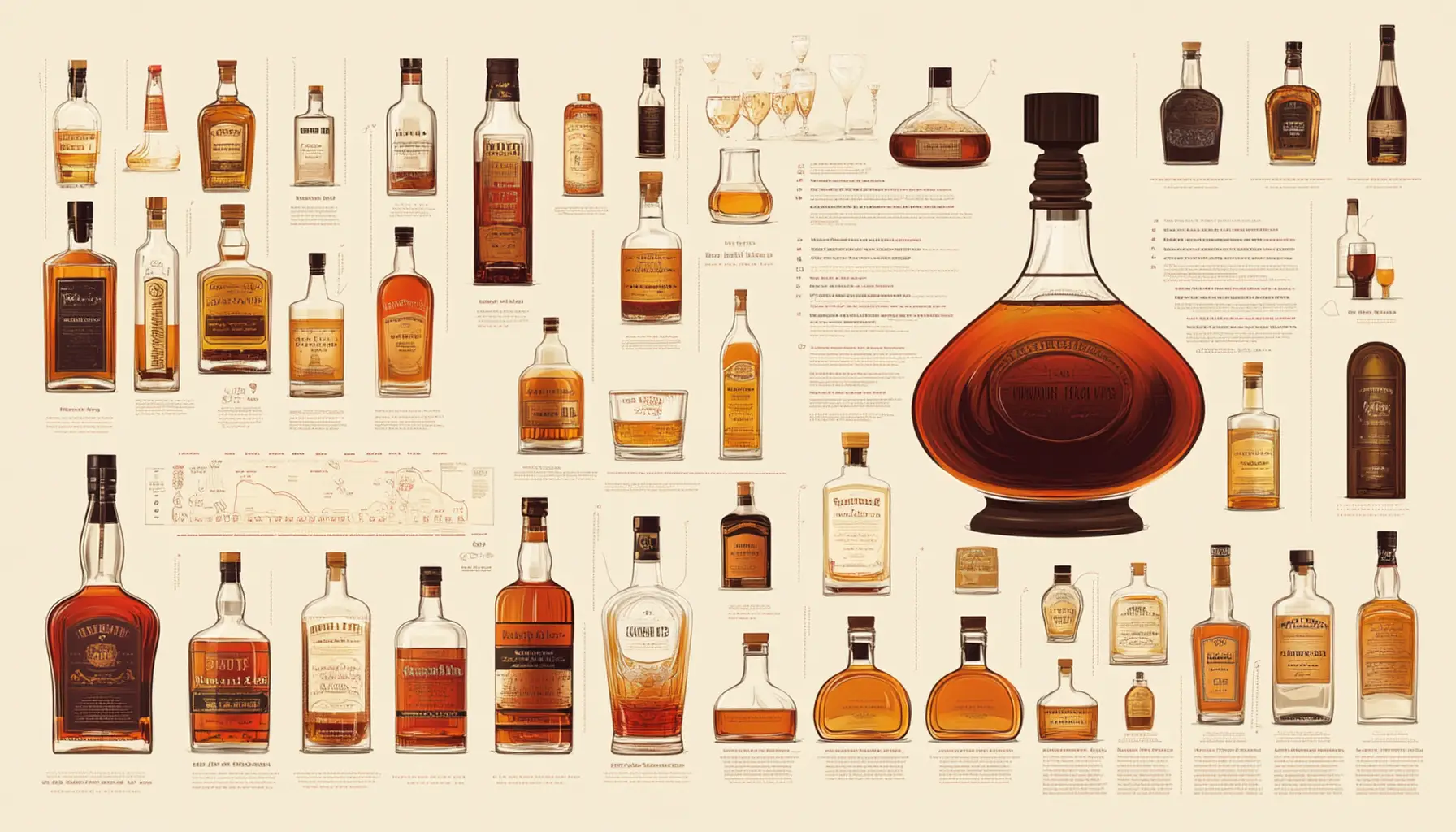

Success Case Studies

Case Study 1: Premium Beverage Brand

A leading soft drink manufacturer increased sales by 35% after switching to custom glass bottles:

- Enhanced product visibility

- Improved shelf presence

- Superior quality perception

- Better taste preservation

Case Study 2: Craft Soda Success

A craft soda startup achieved 45% market growth using premium glass packaging:

- Distinctive bottle design

- Sustainable packaging message

- Premium positioning

- Enhanced brand recognition

Sustainability Features

- 100% recyclable material

- Infinite recycling potential without quality loss

- 95% energy savings when using recycled glass

- Zero chemical leaching

Bulk Ordering Benefits

Volume-Based Pricing Structure

- MOQ: 10,000 units

- Bulk discounts starting at 50,000 units

- Factory-direct wholesale pricing

- Custom mold development available

Conclusion

Custom glass soda bottles represent the perfect fusion of tradition, innovation, and sustainability in beverage packaging. Our rigorous quality control processes and advanced manufacturing capabilities ensure consistent, high-quality products that meet the most demanding industry standards.