In today’s competitive market, understanding the intricacies of glass bottle manufacturing is crucial for businesses in the packaging industry. This article delves into the fascinating world of glass production, exploring the cutting-edge technologies and processes that set top manufacturers like MISA apart.

The Liquor Glass Bottle or Glass Jar Manufacturing Process: From Raw Materials to Finished Product

Let’s break down the glass bottle manufacturing process into eight key steps:

1. Raw Material Preparation and Batch Mixing

The journey of a glass bottle begins with carefully selected raw materials:

- Silica sand (SiO2): The primary ingredient (70-74%)

- Soda ash (Na2CO3): Lowers the melting point (12-16%)

- Limestone (CaCO3): Enhances durability (5-11%)

- Cullet (recycled glass): Improves energy efficiency (up to 50%)

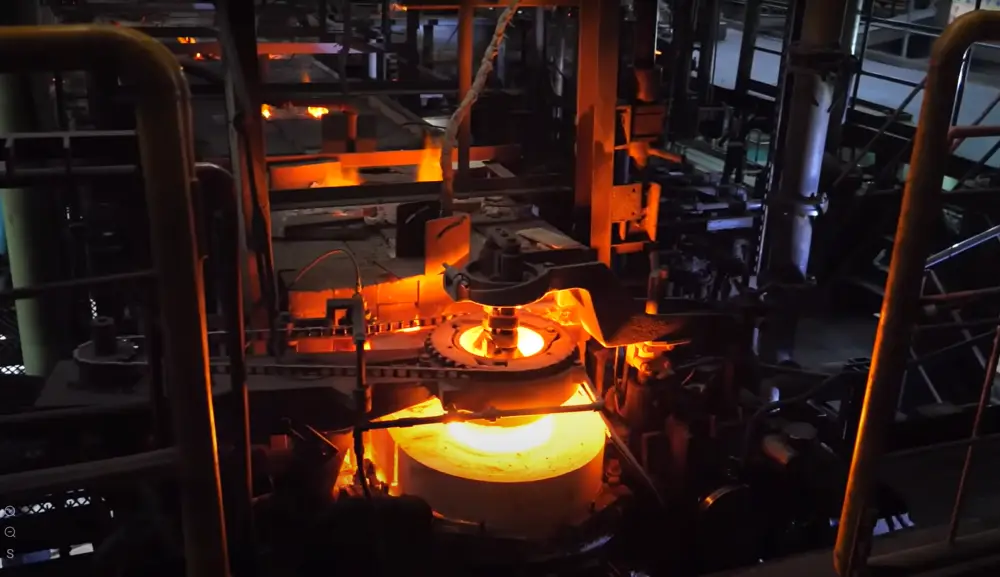

2. Melting and Refining

The batch is melted in furnaces at temperatures reaching 1500°C (2732°F). This process typically takes 24-48 hours and involves two stages:

- Melting: Raw materials transform into molten glass

- Refining: Removes bubbles and homogenizes the composition through a process called “fining”

MISA utilizes state-of-the-art electric furnaces, reducing energy consumption by up to 20% compared to traditional gas furnaces.

3. Conditioning and Feeding

Molten glass flows through forehearths for temperature conditioning, reducing to about 1200°C. It’s then cut into “gobs” of precise weight using a “feeder mechanism” and delivered to forming machines.

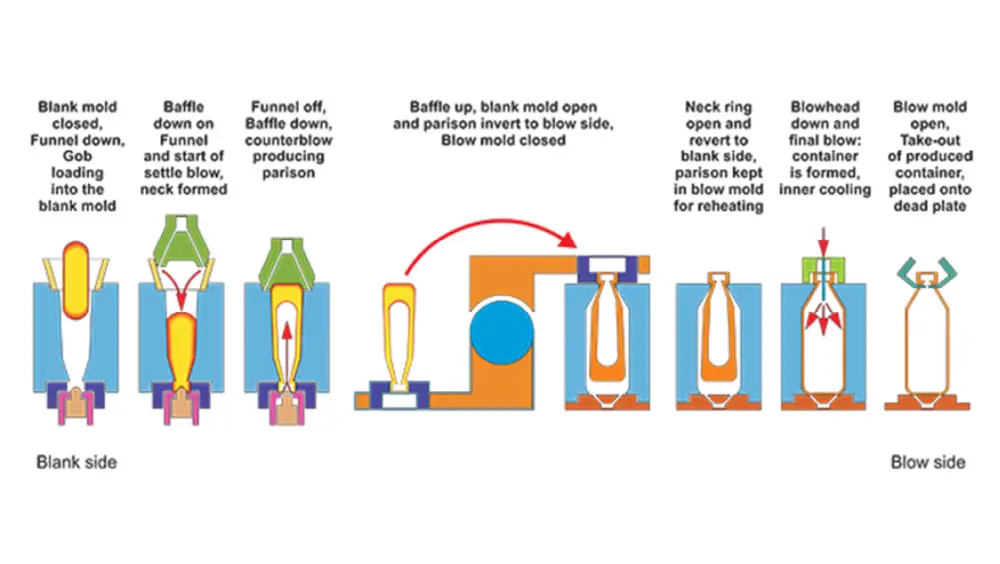

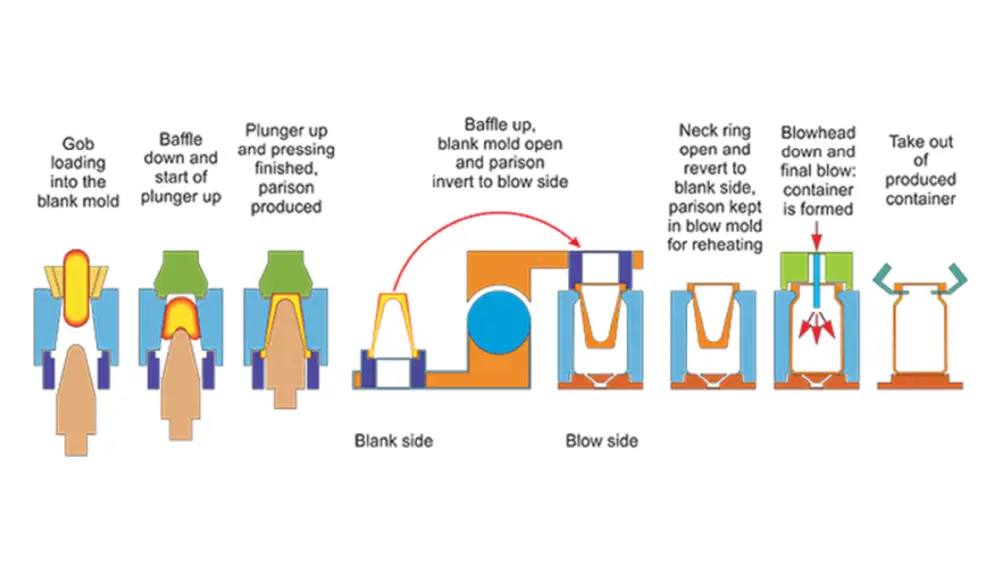

4. Primary Forming

Gobs enter blank molds for initial shaping. Two main methods are used:

- Press and Blow: Ideal for wide-mouth containers

- Blow and Blow: Perfect for narrow-neck bottles

This stage forms the parison or preform. MISA’s advanced IS (Individual Section) machines can produce up to 600 bottles per minute.

Press and Blow vs. Blow and Blow process:

5. Final Forming

The parison is transferred to the final mold where:

- Compressed air is blown into the parison

- Glass expands to fill the mold

- Final bottle shape is formed

MISA utilizes servo-motor control for precise forming, reducing defects by up to 15%.

6. Annealing

Newly formed bottles immediately enter the annealing lehr:

- Slow cooling process eliminates internal stresses

- Enhances bottle strength and durability

Our intelligent annealing systems adjust cooling rates in real-time, optimizing glass strength.

7. Surface Treatment

After annealing, bottles undergo surface treatments:

- Hot end coating: Improves scratch resistance

- Cold end coating: Enhances lubricity and scratch resistance

MISA’s proprietary coating technology improves bottle durability by up to 30%.

[Image: Surface treatment process]

Image name: surface-treatment-process.jpg

Midjourney prompt: “Glass bottles Surface treatment process moving through a surface treatment machine, showing spray nozzles applying coatings, clean industrial setting”

8. Quality Inspection and Packaging

The final step involves comprehensive quality control:

- Visual inspection: Checks for cosmetic defects

- Dimensional inspection: Ensures size accuracy

- Strength testing: Verifies bottle durability

Our automated inspection systems can detect defects as small as 0.1mm, ensuring 99.9% quality consistency.

MISA ‘s Advanced Manufacturing Capabilities

At MISA , we’ve optimized every step of this process:

- State-of-the-art electric furnaces for energy efficiency

- Advanced forming machines with servo-motor control for precision

- Intelligent annealing systems for optimal stress relief

- Cutting-edge inspection technologies for unparalleled quality assurance

Our commitment to innovation and quality ensures that every glass bottle we produce meets the highest standards of excellence. Whether you need large-scale production or customized packaging solutions, MISA is equipped to meet your needs. Contact our expert team today to discuss how we can elevate your glass packaging to new heights.